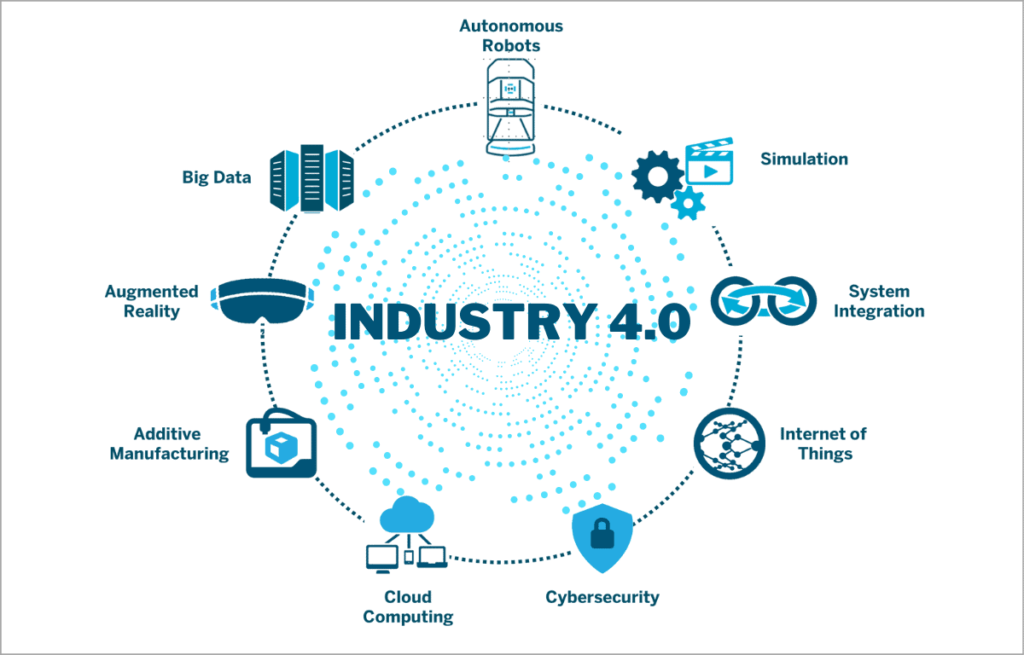

Manufacturing 4.0: Industrial IoT and Smart Factory Implementation

The manufacturing industry is experiencing a profound transformation through the adoption of Industry 4.0 technologies, with Industrial Internet of Things (IIoT) platforms serving as the foundation for smart factory implementations. Recent industry analysis indicates that manufacturers implementing comprehensive IIoT strategies achieve 20-30% improvements in operational efficiency while reducing maintenance costs by up to 40%.

The Smart Factory Foundation

Industrial IoT Platform Architecture

Modern IIoT platforms provide the technological foundation for smart manufacturing operations:

Edge Computing Integration

Real-time data processing at the factory floor level enables immediate decision-making and reduces latency for time-critical operations. Edge computing solutions now handle complex analytics workloads locally while maintaining secure connectivity to enterprise systems.

Unified Connectivity Standards

The convergence of OPC UA, MQTT, and other industrial protocols enables seamless integration between legacy equipment and modern digital systems, creating comprehensive visibility across all manufacturing processes.

1. Predictive Maintenance Revolution

Industry Standard

Advanced predictive maintenance capabilities transform equipment management strategies:

Machine Learning-Enhanced Diagnostics

- Vibration analysis and pattern recognition for rotating equipment

- Thermal imaging integration for electrical system monitoring

- Oil analysis and fluid condition monitoring automation

- Acoustic monitoring for early failure detection

Automated Maintenance Scheduling

- Dynamic work order generation based on equipment condition

- Resource optimization and technician skill matching

- Spare parts inventory optimization and automatic ordering

- Integration with enterprise resource planning (ERP) systems

Production Optimization

2. Real-Time Production Analytics

Operational Excellence

Comprehensive production monitoring provides unprecedented visibility into manufacturing operations:

Overall Equipment Effectiveness (OEE) Optimization

- Real-time availability, performance, and quality tracking

- Automated root cause analysis for production losses

- Continuous improvement opportunity identification

- Benchmarking and performance comparison across facilities

Quality Management Integration

- Statistical process control (SPC) with real-time adjustments

- Automated defect detection using computer vision

- Traceability and genealogy tracking for all products

- Customer complaint correlation and rapid response

3. Supply Chain Integration

Strategic Capability

Smart factories integrate seamlessly with supply chain partners and logistics providers:

Demand-Driven Manufacturing

- Real-time demand sensing and production adjustment

- Supplier integration and collaborative planning

- Automated purchase order generation and expediting

- Inventory optimization across the value chain

Logistics and Warehouse Automation

- Automated guided vehicle (AGV) integration and coordination

- Real-time inventory tracking and location management

- Optimized picking and packing operations

- Integration with transportation management systems

Advanced Manufacturing Technologies

4. Digital Twin Implementation

Innovation Driver

Digital twin technology enables virtual representation and simulation of manufacturing processes:

Process Simulation and Optimization

- Virtual commissioning and testing of production lines

- Scenario modeling for capacity planning and optimization

- Energy consumption modeling and sustainability planning

- New product introduction (NPI) risk reduction and timeline acceleration

Equipment Digital Twins

- Virtual equipment modeling for design optimization

- Predictive modeling for equipment performance and lifecycle

- Remote troubleshooting and technical support capabilities

- Training simulation and operator skill development

5. Additive Manufacturing Integration

Emerging Technology

3D printing and additive manufacturing technologies integrate with traditional production systems:

On-Demand Manufacturing

- Spare parts production and inventory reduction

- Customized product manufacturing and mass customization

- Rapid prototyping and design iteration acceleration

- Decentralized manufacturing and supply chain resilience

Quality Control for Additive Manufacturing

- Layer-by-layer quality monitoring and control

- Post-processing automation and finishing operations

- Material certification and traceability

- Integration with traditional manufacturing quality systems

Workforce Transformation

Augmented Reality and Virtual Training

Manufacturing organizations implement AR/VR technologies for workforce development:

Maintenance and Repair Guidance

- Step-by-step visual instructions overlaid on equipment

- Remote expert assistance and knowledge sharing

- Training simulation for complex procedures

- Safety protocol reinforcement and compliance monitoring

Quality Inspection Enhancement

- Visual inspection guidance and error prevention

- Measurement and calibration assistance

- Documentation automation and record keeping

- Continuous improvement feedback collection

Cybersecurity for Manufacturing

6. Industrial Cybersecurity Framework

Critical Requirement

Manufacturing environments require specialized cybersecurity approaches:

Network Segmentation and Monitoring

- Operational technology (OT) and information technology (IT) network separation

- Industrial firewall deployment and configuration

- Continuous network monitoring and threat detection

- Incident response procedures specific to manufacturing environments

Device Security and Management

- Industrial device inventory and vulnerability management

- Secure remote access for vendors and technicians

- Firmware update management and testing procedures

- Zero trust architecture implementation for industrial systems

Implementation Strategy

Phased Digital Transformation

Successful smart factory implementations follow structured approaches:

Phase 1: Foundation Building (Months 1-6)

- Current state assessment and digital readiness evaluation

- Network infrastructure upgrade and security implementation

- Basic data collection and visualization deployment

- Pilot area selection and initial proof-of-concept development

Phase 2: Core Capabilities (Months 7-18)

- IIoT platform deployment and integration

- Predictive maintenance program implementation

- Production analytics and optimization tool deployment

- Workforce training and change management programs

Phase 3: Advanced Integration (Months 19-36)

- Digital twin development and simulation capabilities

- Advanced analytics and artificial intelligence implementation

- Supply chain integration and collaborative planning

- Continuous improvement and innovation programs

Sustainability and Environmental Impact

Energy Management and Optimization

Smart factory technologies enable comprehensive energy management:

Real-Time Energy Monitoring

- Equipment-level energy consumption tracking

- Peak demand management and load balancing

- Renewable energy integration and optimization

- Carbon footprint calculation and reporting

Waste Reduction and Circular Economy

- Material waste tracking and reduction initiatives

- Recycling program optimization and automation

- Byproduct utilization and value recovery

- Sustainable packaging and logistics optimization

Industry-Specific Applications

Automotive Manufacturing

The automotive industry leads in smart factory adoption:

- Just-in-time (JIT) production optimization and supplier integration

- Quality control for safety-critical components

- Flexible manufacturing for multiple vehicle platforms

- Integration with autonomous vehicle testing and validation

Aerospace and Defense

Aerospace manufacturers implement specialized IIoT capabilities:

- Traceability requirements for safety and regulatory compliance

- Complex assembly process optimization and error prevention

- Material certification and quality documentation

- Long-term lifecycle management and sustainment support

Return on Investment and Business Impact

Quantifiable Benefits

Organizations implementing comprehensive smart factory strategies report significant improvements:

Operational Metrics

- 15-25% reduction in manufacturing costs

- 20-35% improvement in equipment effectiveness

- 30-50% reduction in unplanned downtime

- 10-20% improvement in product quality metrics

Strategic Benefits

- Faster time-to-market for new products

- Enhanced customer satisfaction and loyalty

- Improved workforce safety and engagement

- Increased operational flexibility and resilience

The transformation to Manufacturing 4.0 represents more than technological advancement—it signifies a fundamental shift in how manufacturers create value, serve customers, and compete in global markets. Organizations that successfully implement comprehensive smart factory capabilities will achieve sustainable competitive advantages through improved efficiency, quality, and innovation capacity.